Our specialized design team can turn your predesigned parts or conceptualize new product ideas and turn them into real tangible products. Latest designing software such as Autocad, Pro-E, Ansys, Catia and other surface modeling tools are used in order to minimize design time and achieve perfection in prototype models. R & D facility also include Material research testing and validation, Thermal & Structural Noise Vibration Hardness (NVH) Study.

2 D CAD Drawing

3 D CAD Drawing

CAD Rendering

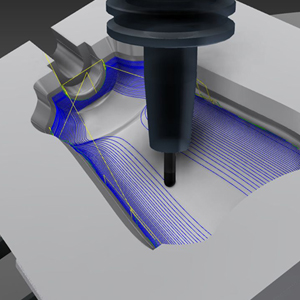

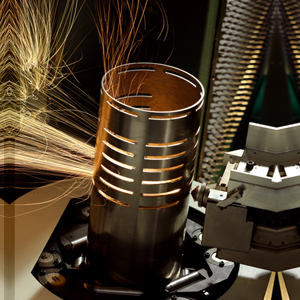

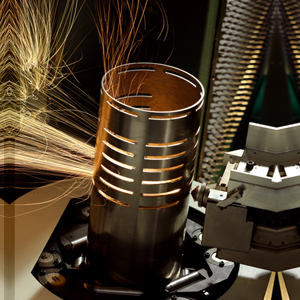

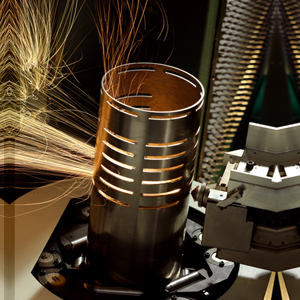

Generally the first process on row material includes turning, drilling, milling, plaining, shaping, broaching etc. with the advent of industrial era we have moved from manual operations to computerized machining processes.which have helped to maintain accuracy and reduce production lead times.

We employ CNC vertical milling machines,modernlaiths ,Lazer and water jet cutting machines, CNC drills and bending and for minute jobs, Electrical discharge machines are also extensively used.

NC Machine

CNC machine

Lazer Cut

CNC Bending

For in house requirement various dies, Jigs, fixtures molds are designed and manufactured. These include cutting dies, bendingdies, plastic molding dies. Zinc and Aluminum dies for various parts. CNC Machining centers such as MIKNONHSM-700 ,Decalf FP-50-CP, EDM Machines Rovella BF-600, wire cutting EDM- Electronica Euro- Cut Mark-2 are employed to achieve least design and production times.

Plastic Die

Steel Die

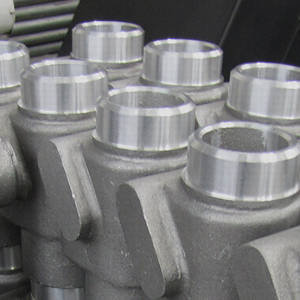

Solidification of molten liquids is undertaken at our various hired facilities, Metal casting including Ferous( Grey or Dectile iron). Zinc and Aluminum casting is undertaken for various Auto heavy industry, Building Industry.

Epoxy, Polyester, Casting Facility is also available. Scientific stimulation methods to calculate the quality of the cast component, Mold filling, Solidification and Quantative prediction of the mechanical properties, Thermal stresses, distortion of cast product is also undertaken to maintain quality control.

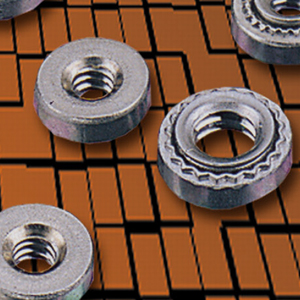

Plating is one of the most critical process which not only help to finish the object but also improves hardness, wearability and inhibits corrosion thus ensuring longer lifetime. Zinc( Alkaline – non Alkaline plating, crome, alloy, gold or silver facilities are available, other plating options such as vapour deposition under vacuum and sputter and metalizing facilities are available.

Various Finishing processes such as painting, Powder coating, Sand blasting, Buffing / laping or Vibrator finishing are bing implemented.

In order to deliver numerous large quantity of product, Various production tools are employed. Manual/ Mechanical assembling of large equipment is possible at very competitive and affordable prices. Multi Part assembling with the help of specially design jigs and tools is also offered to our regular esteemed clients.

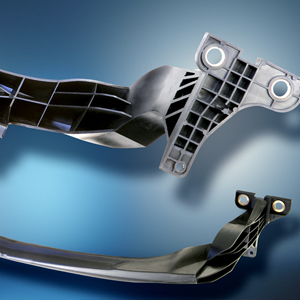

Injection molding through third party or in house built molds is available for all sizes of products from 6mm to 600mm up to 1Kilogram. 3-D printing of parts is also undertaken for prototyping or productionof fewer parts. Various Polymers for production of these parts includes polycarbonate (GE/LEXAN/BASF/EXXON/ABS/PP/NYLON/ PPCP)

List of Parts:

Polycarbonate Light covers

ABS front lamp covers

Nylon Screws

ABS Connectors

Sheet Metal

Sheet Metal Boxes

Sheet Metal Connectors

MS Components

Steel threaded shafts

Aluminum LED light bodies

Aluminum under water lights

Gun Metal valves

With our varied and extensive experience, we guarantee that we shall meet your designs/specifications and shall deliver you the right product at the lowest cost. Our Manufacturing team powered by our intelligent designers along with our subsidiaries design and build complex products in the most cost effective manner.

Cash in the lower labor /overhead/raw material cost in the Indian industry. With Protele Engineers you can be assured of fair and long term business dealings. We have remained the leaders in innovations and produce some of the novel products such as Polycarbonate under water Light fitting,Glass Aluminum connectors, Polycarbonate Covers Etc.

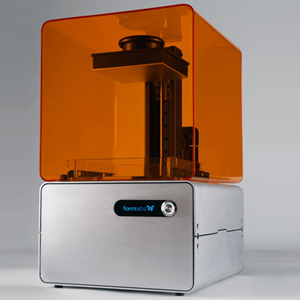

Keeping abreast with the latest manufacturing tools ,Protele is also pioneering the 3D Printing Space. Additive manufacturing has helped the industry in cutting down prototype costs and ensured least lead times. Our in house 3D Printers help us in rapid prototyping and creating models which help us in analyzing the products from various prospective of engineering.

Our quality control focus panes across well defined and manged processes including identification and generation of record and use of control charts help us to setup total quality management across the organization. Various processes are monitored under various standards including 6 sigma. Continuous improvement under Kaizen methodology including performance feature, reliability, conformance , Durability, Serviceability, aesthetic and perceived quality form the bases at a strategic level to analyze quality characteristics. Random Sampling or 100% Checking as defined by the Protele/Client manual strictly follow to ensure that nothing unwanted passes through to the valuable customer.